How lasers work

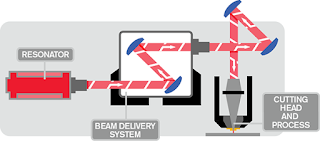

How a CO2 laser works How a CO 2 laser works In a CO 2 laser, high voltage is applied to a mixture of CO 2 , N 2 , and He in the resonator generating the laser beam. The laser beam is then reflected and shaped by a series of mirrors that deliver the laser beam to the cutting head. How a fiber laser works In a fiber laser, a low-maintenance solid-state laser source generates a laser beam that is delivered through a fiber optic cable to the laser head. The glass fiber transfers the beam with a beam quality tailored for the cutting task at hand. If you want to buy fiber laser cutting machine , We are your best Choice .